District: Grain Valley School District

Industry: Education

Location: Grain Valley, Missouri

Vehicles: (14) 2018 IC Bus CE Series propane autogas-fueled buses

Fueling: On-site propane autogas station

Challenge

With aging diesel buses to replace, a Missouri school district looked to alternative fuel options that would save money on fuel and maintenance.

Result

The Grain Valley School District purchased 14 propane school buses. The new buses joined a 49-bus fleet that transports 2,800 students to school from subur ban and exurban neighborhoods.

ban and exurban neighborhoods.

Focus on Cost-Cutting

Over the years Missouri state reimbursements for school transportation have dropped from 75 percent to 16 to 20 percent. School districts in the state have had to tap their own general school funds to make up the shortfall.

To help save money, the Grain Valley district considered alternative fuels for its new school buses and comparing compressed natural gas (CNG) and propane autogas. District representatives attended an alternative fuels workshop hosted by Kansas City Regional Clean Cities, a Metropolitan Energy Center program. The district considered various fuels but “the vehicle costs and fueling station costs for CNG were much higher versus propane,” said Shawn Brady, director of transportation.

The district decided to purchase 14 propane buses in 2018 to replace diesel buses of 2001 and 2002 model years. Brady researched and applied for a grant from the U.S. Department of Energy through Kansas City Regional Clean Cities to assist with the purchase costs of the buses.

Preparing for Propane Autogas

To fuel the new buses, the district entered into a contract with their local propane provider, Ferrellgas. A fueling station with two 1,000-gallon tanks was built in the school district’s bus parking lot in April 2018. “It saves time not to have to travel to refuel,” Brady noted.

Infrastructure costs for propane are the lowest of any fuel; alternative or conventional. For Grain Valley schools, the start-up cost for the fueling station totaled $16,500. “We received a 45 percent grant from Metropolitan Energy Center for the installation of our propane fueling station,” Brady said. The center’s grant amounted to $7,425. “The fueling station cost us only $9,075 after the grant.”

Before putting the new buses on the district’s routes, drivers received training in propane bus operation. “Our bus vendor provided training on how to properly operate the buses and maximize fuel efficiency,” Brady said. The district’s technicians traveled to the bus manufacturer’s factory in Tulsa, Oklahoma, for a complimentary week-long training course on maintenance. The district didn’t need to make changes to its bus repair facility. Requirements for a propane vehicle service facility are generally the same as those for conventionally fueled vehicles.

Financial Benefits

After tapping grants for purchase assistance, each new bus cost about $250 more than a comparable diesel bus. District officials say that the higher initial cost can be quickly recouped in fuel savings.

In fact, by adding propane buses to its fleet, Grain Valley School District has noted savings on both fuel and maintenance. On average, propane autogas costs up to 50 percent less than diesel. As part of its  negotiated contract, Grain Valley paid a locked-in rate of $1.20 per gallon of propane in 2018-1019. For the 2019-2020 school year, the district pays $1.15 per gallon. For comparison, the district pays $2.31 per gallon on average for diesel.

negotiated contract, Grain Valley paid a locked-in rate of $1.20 per gallon of propane in 2018-1019. For the 2019-2020 school year, the district pays $1.15 per gallon. For comparison, the district pays $2.31 per gallon on average for diesel.

Each bus in the district runs about 9,000 miles per year. For the 2018-2019 school year, fuel savings amounted to about $14,500. “The district’s increased savings year after year will allow the transportation department to serve as a better steward of taxpayer money,” said Brady.

Additional savings come from the reduced maintenance. With propane autogas, no exhaust after-treatment or diesel emissions fluids are required like with diesel to meet today’s strict emissions regulations. Propane vehicles don’t need particulate trap systems, turbochargers and intercoolers. Plus, propane uses less engine oil. All these factors contribute to the overall savings of time and money. The district’s technicians like the propane buses, Brady reports. “There are fewer parts and systems to have to maintain.”

However, Brady explained that “warranty work is challenging with no established shop in Kansas City.” He noted that IC does provide a traveling technician who assists his staff when they encounter maintenance issues. Kansas City Regional Clean Cities recommends fleet managers ensure that there is a local service shop to do warranty and continuing work on buses before purchasing.

Even more saving shows up for the district in the winter. Due to the chemical properties of propane autogas, the propane buses warm up faster and have no cold start issues. Unlike diesel vehicles, these buses can start up in temperatures as low as -40 degrees Fahrenheit. School districts report lower electric costs because the propane buses don’t rely on block heaters. “Our propane buses warmed up faster this past winter than the diesel buses,” Brady said.

Beyond the Bottom Line

Grain Valley’s propane buses are helping the community’s air quality. Unlike diesel buses, propane vehicles emit virtually no particulate matter and, with substantially less nitrogen oxides (NOx). Buses fueled by propane also emit fewer greenhouse gases and total hydrocarbon emissions when compared to diesel buses. Propane’s quiet operation makes riding the bus more pleasant for passengers and safer for drivers, who are less distracted by engine noise. “We’ve benefitted from much cleaner air and much quieter buses running through neighborhoods,” said Brady.

Drivers also report that the propane dispenser pumps are just as fast or faster than the diesel fuel pump when it’s time to fill the tank. The district notes that it will be sure to order buses with 100-gallon fuel tanks going forward. “These were not available from IC when we placed our first order,” Brady said.

The district’s leadership in adopting an alternative fuel earned it a 2018 Agent of Change Award from the Metropolitan Energy Center, a Kansas City nonprofit catalyst for energy efficiency, economic development and environmental vitality.

The district’s plan to purchase seven more propane buses this year, and eventually move to an all-propane fleet, speaks to the administration’s belief in the benefits of this alternative fuel for their students, drivers and overall community.

“Our district made the decision on propane buses to save money. The environmental impact is an added benefit. There’s no reason to not make the move into propane now,” Brady said.

About MOPERC: The Missouri Propane Education & Research Council is a not-for-profit organization authorized by the Missouri Legislature. Dedicated to propane education and public awareness, MOPERC provides industry training, consumer safety, appliance rebates and market development programs. The council is composed of 15 volunteer directors and adm inistered by an executive staff. Visit PropaneMissouri.com.

By: Meggan Shoberg

The health and safety of students in the classroom is of crucial importance. According to the U.S. Department of Education, currently 55 million people spend their time in K-12 buildings. That is about 20 percent of our current population! Teachers, students, administration, and staff are all spending a majority of their time indoors, between the walls of these vital buildings. The students who reside in these buildings consume more oxygen than their adult counterparts, and are afflicted by poor indoor air quality, inefficient energy systems and health risks at a higher rate.

Many Midwest schools have been recipients of Energy Star Awards, and that is an amazing first step to creating the best environment for learning. There are a couple of key considerations to make when analyzing your school building’s efficient and indoor air quality:

- Energy Star and other energy benchmarking programs are a standard for adults, not children. So, area schools should be looking to not just achieve minimum standards, but exceed them to accommodate their most vulnerable residents.

- Look at the building’s efficiency during occupied periods of time. While over a 24-hour period, a school may warrant acceptable results, these facilities are unoccupied a portion of the time and experience high traffic during school hours. Energy efficiency measures should account for the time that the building is actually using energy, not when it’s sitting dormant.

Over the next few months, we will be diving into the topic of efficiency, maintenance and indoor air quality of schools. We’ll be covering the benefits, low-cost improvement measures, EPA tools, and how Metropolitan Energy Center is a great partner for your school’s efficiency project. Stay tuned in the coming months as we explore this critical compenent to protecting the health of our students, and contact Meggan@metroenergy.org with questions about how your school can improve its efficiency.

Guest Blog by Jane Hinds; Edited by Natalie Phillips

City of Columbia, Missouri Water & Light was recognized as one of the Department of Energy’s 2019 ENERGY STAR Partners of the Year. The City also achieved this award in 2018. This prestigious accomplishment recognizes Water & Light’s innovative and inclusive approach

to energy efficiency and its efforts to iterate and expand offerings to reach new clients, and improve more homes and rental properties. Applicants are evaluated based on collaboration with other utility providers, the accessibility of their programming and

the extent of the “whole-house approach” being accomplished.

“We are very excited to earn this award for a second year,” Director of Utilities Tad Johnsen said. “Since we initiated our Home Performance with ENERGY STAR program, we have been tailoring our programming to better coordinate with our partners and meet community needs while supporting other City initiatives. Receiving this recognition validates our efforts and incentivizes us to work towards higher goals.”

The 2019 ENERGY STAR Award winners are industry leaders in the production and sale of energy-efficient products and services, and in the development and adoption of strategies that provide substantial energy and money savings in the buildings where we live and

work. Columbia’s Home Performance with the ENERGY STAR program uses a whole-house approach to energy efficiency and offers rebates and low-interest loans to help residents achieve their energy efficiency goals. Average Home Performance participants see a twenty-five percent savings on their heating and cooling costs.

This program was initiated in 2008 and the Utility has since introduced additional programs such as the Employee Outreach Program which offers employees free home energy efficiency assessments, Enhanced Home Performance and Enhance Your Attic which focus on increasing access to income eligible residents, and Attic Plus which incentivizes landlords to insulate attics in smaller duplexes and condos with less attic space. Water & Light staff members also provide a Building Performance Institute certified contractor training

program, and partners with local co-op Boone Electric, to create consistency to ensure that all Columbia’s residents have the opportunity to benefit from energy efficiency improvements.

For more information about the City’s programming, visit ColumbiaPowerPartners.com.

Metropolitan Energy Center and Grain Valley School District, in conjuction with the national nonprofit Propane Education & Research Council, hosted the “Autogas Answers for Schools Workshop” Friday at the Courtyard Marriott Kansas City East/Blue Springs. The workshop explained the advantages of running school bus fleets on propane autogas and showed Grain Valley’s propane-powered school bus fleet in action.

“When schools choose to incorporate propane into their bus fleets, the whole community benefits,” said Kelly Gilbert, executive director of Metropolitan Energy Center and coordinator of Kansas City Regional Clean Cities. “This event was a fantastic opportunity for Kansas City school transportation officials to see how propane autogas buses are already working for the local Grain Valley School District. We hope everyone who attended left feeling empowered to make the best decision for their fleet, their students and their community.”

During the event, the Grain Valley School District provided a tour of their scalable propane autogas refueling infrastructure. As of January 2019, nearly 30 percent of Grain Valley’s fleet is powered by propane autogas. The Grain Valley Director of Transportation, Shawn Brady, plans to add seven more propane-powered buses by the end of the year.

Propane professionals expanded upon Grain Valley’s testimonial by explaining how propane-powered school buses can reduce a fleet’s emissions and offer the lowest total cost-of-ownership of any fuel, in part because of lower fuel and maintenance costs. Attendees also learned about clean transportation funding opportunities and networked with clean fuel industry professionals.

Nathan Ediger of Ferrelgas discusses propane infrastructure at Grain Valley SD.

The Autogas Answers for Schools Workshop was put on by Grain Valley School District, Metropolitan Energy Center, Kansas City Regional Clean Cities, Propane Education & Research Council, Missouri Propane Gas Association, the Kansas City Area Association of Pupil Transportation, and Ferrellgas. For more information about Metropolitan Energy Center, visit metroenergy.org.

About Metropolitan Energy Center: Metropolitan Energy Center is a non-profit and a catalyst for energy efficiency, economic development and environmental vitality in America’s Heartland. It is host of Kansas City Regional Clean Cities, a designated U.S. Department of Energy program, and Central Kansas Clean Cities. Learn more about us and our programs at metroenergy.org.

About PERC: The Propane Education & Research Council is a nonprofit that provides leading propane safety and training programs and invests in research and development of new propane-powered technologies. PERC is operated and funded by the propane industry. For more information, visit propane.com.

By: Mary English

Those that have been in the lighting business a long time can probably remember the struggle of energy efficient lighting: The product came into the market higher priced than their older cousins, the fluorescent light bulb. They were too bright. Too white. What was the benefit?

The benefit, it turned out, was energy savings. Lots and lots of energy savings. (Some would say the aesthetics have since caught up to this benefit as well.) However, since the habit was to change out light bulbs once the old ones aged and burned out, the lighting retrofit took a while to gain traction.

We now find ourselves in the same situation with a new product package in the commercial market: the humble motor, fan, and VFD packaged retrofit for HVAC and refrigeration.

HVAC takes up to 30-50% of your utility bills according to the US Department of Energy and field experts — and the vast majority of commercial properties are wasting money on inefficient equipment. This is due to manufacturers cutting costs with the original cheaper components to boost margin. One of these main components is the motor that drives the air flow in forced air systems.

There has been a new kid in town for quite some time, but it remains virtually unknown to those in the energy efficiency business: electronically commutated motors (ECM). These motors are 70% more efficient than their older cousins, the shaded pole motor. This technology has been around for decades, but has remained virtually unused since it hasn’t been mandated by code.

The mandate for brand new equipment is about to change from the DOE this June for brand new installs, but this still leaves almost 90% – including relatively new systems – in HVAC and refrigeration installed with these old motors that burn through your utility dollars much like the old incandescent light bulbs. Most people upgrade their equipment when it breaks down, just like businesses waited until their light bulbs burned out in the old days. This thinking is short sighted, especially when you see how much impact on energy use a new motor retrofit can have on your bottom line.

A Kansas City based company – FridgeWize – is out to change minds and bring awareness to this opportunity in the commercial market. They are uniquely positioned in that they are the only company in the U.S. with a business model to retrofit high efficiency ECM’s to end-user businesses and property owners nationwide.

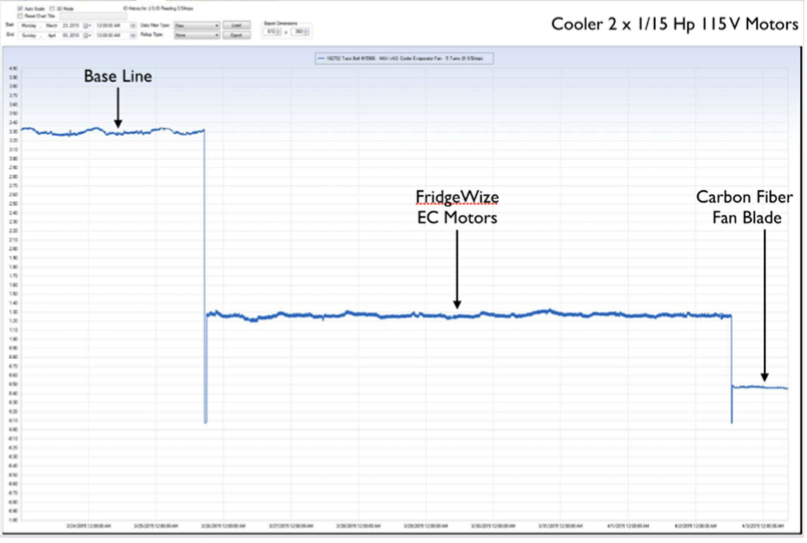

Founded in 2010, they have already done retrofits nationwide in major chain restaurants. One such nationwide retrofit saved over 5-million kilowatt hours (kWh) over 450 restaurant locations – that is the equivalent of a 2 megawatt solar field (at almost five times less the cost of renewable installs). For energy wonks, the numbers are fun to see. In refrigeration, FridgeWize consistently sees 80-90% energy savings when retrofitting an old shaded pole motor with an ECM and their own carbon fiber blade where they have a patent pending (see Image 1) on the walk-in cooling units.

Image 1. Testing measurement of energy pull via amps from old motor (Base Line) to new ECM and carbon fiber blade for walk-in storage refrigeration.

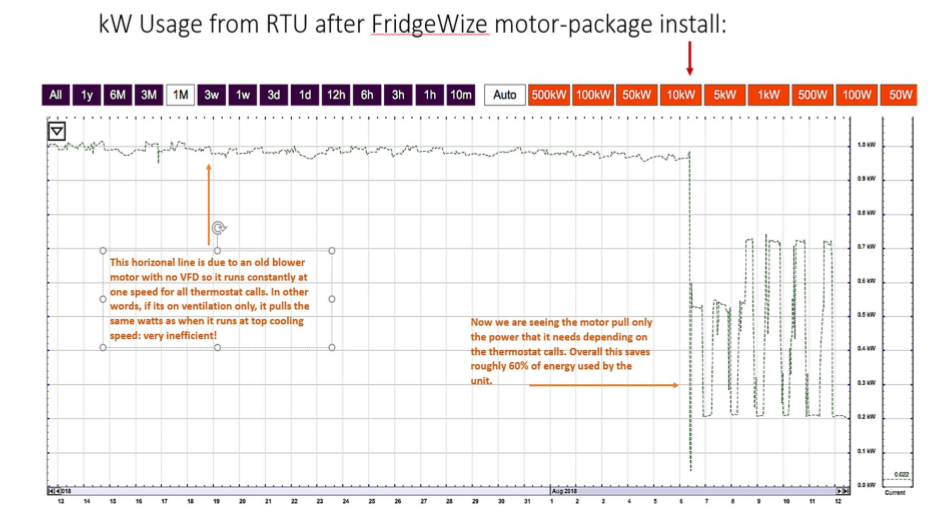

In more traditional HVAC air delivery – such as roof top units, air handlers and VAV fan boxes – the kWh savings are not as aggressive, but still better than any other more common retrofits in the industry; and roughly 10% the cost of replacing an entire HVAC system. FridgeWize in several case studies has seen roughly 60% reduction in kWh’s on the power needed to operate the blower fans when using ECM’s along with a variable speed drive (VFD). This is illustrated in Image 2.

Image 2. Before and After an ECM plus VFD and smart card install on a roof top unit at a large manufacturing facility in the Kansas City area.

FridgeWize has seen validation in the last several years through international awards won in the industry. In 2016 they won the illustrious Energy Efficient Product of the Year for HVAC&R. The firm’s CEO, Ryan Grobler, was presented the award in London after beating out high profile products from the likes of Mitsubishi and Samsung manufacturers.

“We are excited to be in Kansas City as this community thrives in sustainable leadership. We have been flying below the radar, but with the aggressive rebates being offered by KCP&L for our products, we don’t think we will be a secret much longer,” said Grobler. “With the rebates, we’re looking at return on investment for these retrofits in 1 – 2 years max.”

The rebates Grobler mentioned are the 75% HVAC bonus rebate being offered by KCP&L through September of this year, or when the money runs out – whichever comes first.

For more information on FridgeWize and their retrofit products, they can be reached at 913-579-8484 or info@fridgewize.com.

About Us

Metropolitan Energy Center (MEC) is a 501(c)(3) nonprofit organization. Our mission is to create resource efficiency, environmental health, and economic vitality in the Kansas City region – and beyond. Learn more about us and our programs.

Some images courtesy of all-free-download.com